SMALL DIAMETERS FUSION

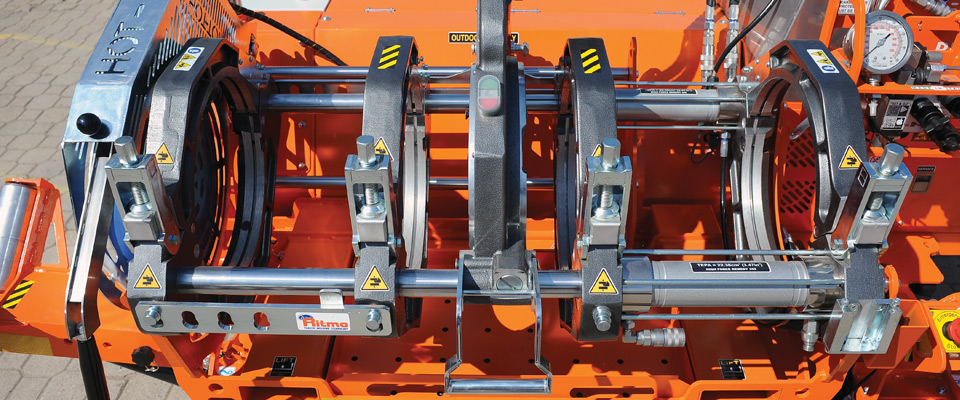

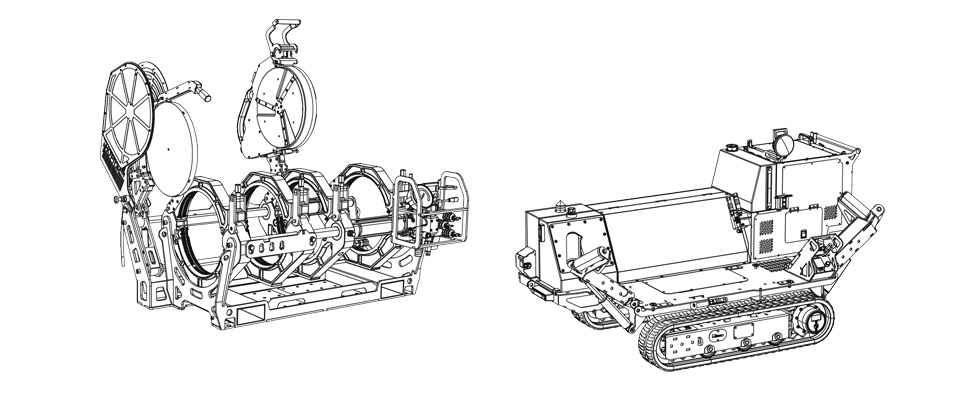

REMEDY 355 is an independent, high-productivity welding machine driven by tracks and powered by a Diesel on-board generator. Designed for butt

welding HDPE and PP pipes from Ø 125 to 355 mm (from 4” to 14” IPS; from 4” to 12” DIPS). Suitable for ISO 21307 High Pressure and ASTM F2620 fusion standards.

Versatile

- Working range

from Ø 4” to 14”IPS

from Ø 4” to 12” DIPS

from Ø 125 to 355 mm

- Materials: HDPE, PP

- Manual controls

- Tracked welding machine

- Drives over 35% slopes

- In-ditch/user friendly

- In-ditch hoses/cables range/length 7 m - 23 ft Accurate

- Designed to weld according to:

ISO 21307 High Pressure

ASTM F2620 standards

- Removable auxiliary panel to control

facer/heating plate

- Easily welds fittings/quick set-up time

- Heating plate with a high temperature

protection

- Spotlights on welding area

- Insert with fast-locking system

Complete

- Self-propelled on track

- Self-contained generator on-board

- Heater/facer on-board

- Patented System to open/close

Heating plate and Facer

- Hydraulic side rollers

- Facer with safety microswitch

FREE TO CONTROL

Remedy 355 is available with Manual Welding Control System. Intuitive control panel allow an easy menagement of the welding

cycle and every phase is manually controlled.

REMEDY 355 is an independent, high-productivity welding machine driven by tracks and powered by a Diesel on-board generator. Designed for butt

welding HDPE and PP pipes from Ø 125 to 355 mm (from 4” to 14” IPS; from 4” to 12” DIPS). Suitable for ISO 21307 High Pressure and ASTM F2620 fusion standards.

Versatile

- Working range

from Ø 4” to 14”IPS

from Ø 4” to 12” DIPS

from Ø 125 to 355 mm

- Materials: HDPE, PP

- Manual controls

- Tracked welding machine

- Drives over 35% slopes

- In-ditch/user friendly

- In-ditch hoses/cables range/length 7 m - 23 ft Accurate

- Designed to weld according to:

ISO 21307 High Pressure

ASTM F2620 standards

- Removable auxiliary panel to control

facer/heating plate

- Easily welds fittings/quick set-up time

- Heating plate with a high temperature

protection

- Spotlights on welding area

- Insert with fast-locking system

Complete

- Self-propelled on track

- Self-contained generator on-board

- Heater/facer on-board

- Patented System to open/close

Heating plate and Facer

- Hydraulic side rollers

- Facer with safety microswitch

FREE TO CONTROL

Remedy 355 is available with Manual Welding Control System. Intuitive control panel allow an easy menagement of the welding

cycle and every phase is manually controlled.

Technical features:

Materials

HDPE/PP

Ø 4” ÷ 12” DIPS

Ø 125 ÷ 355 mm

Fuel tank

9.86 x 4.85 x 5.54 ft